Turn-Key Solutions & Special Purpose Machines

Avismatic Solutions design and manufacture a complete range of conveyor solutions, including straight transfer; radius; elevator and de-elevator; multilane and merge; spiral elevator and de-elevator; packing stations, inspection and grading; basket, crate and tray; hygienic and plastic construction. Avismatic Solutions can supply a single conveyor unit, through to a complete turnkey plant solution.

TUNRKEY SOLUTIONS

Our focus is on developing full line conveyors. We produce a tailor-made systems for our customers designed especially for specific products. Your requirements is top priority. We offer you a consistent support with a lot of value-add, all under one roof i.e. planning, construction, production, control, programming, assembly and commissioning.

TURN-KEY PROJECTS and SPECIAL PURPOSE MACHINES/SYSTEMS

Turn-key Projects - We provide turn-key solutions for integration of primary as well as secondary packing processes with PLC Control system for the following applications:

- • Raw material handling

- • Snack-food processing

- • Complete system integration from pouch/bagging system up to warehouse delivery

- • Complete system integration of delicate food products such as confectionery, biscuits, granules, powders, etc. for secondary packaging into jars, tins, small containers and further to downstream machinery.

- • End of line case handling, taping, sorting, distribution, etc.

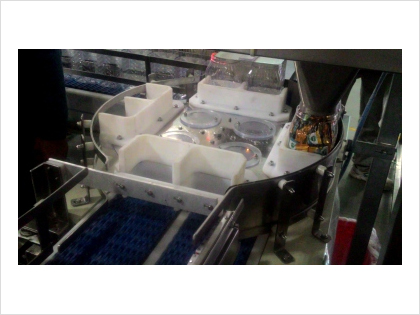

Multi-lane Jar filing system

Seasoning/Flavoring Application

Complete system with PLC control panel & HMI for flavour application to products like RTE, Crispies, Snacks, Wafers, Indian Namkeen, etc. These are custom designed systems based on product nature, throughput and plant constraints. The typical set up comprises of a coating pan or a small tumbler, a dosing system, handing system and control system. The dosing system can be for DRY, WET or BOTH. The process can be designed for both batch as well as continuous processing.

Flavor Preparation Systems on Skid

Food processing plants require flavors to be added on the base products. We design a complete flavor preparation skid for dry as well as wet (slurries) flavours. The system typically comprises of a pair of mixing kettle (preparation and use) for oil based slurries OR a mechanical mixer (ribbon blender) for dry flavors, a dosing system (volumetric or gravimetric).

Our 3 unique Systems

Multi-lane Jar filing system

Rotary Jar Filing System

Batch & Continuous Flavouring Systems